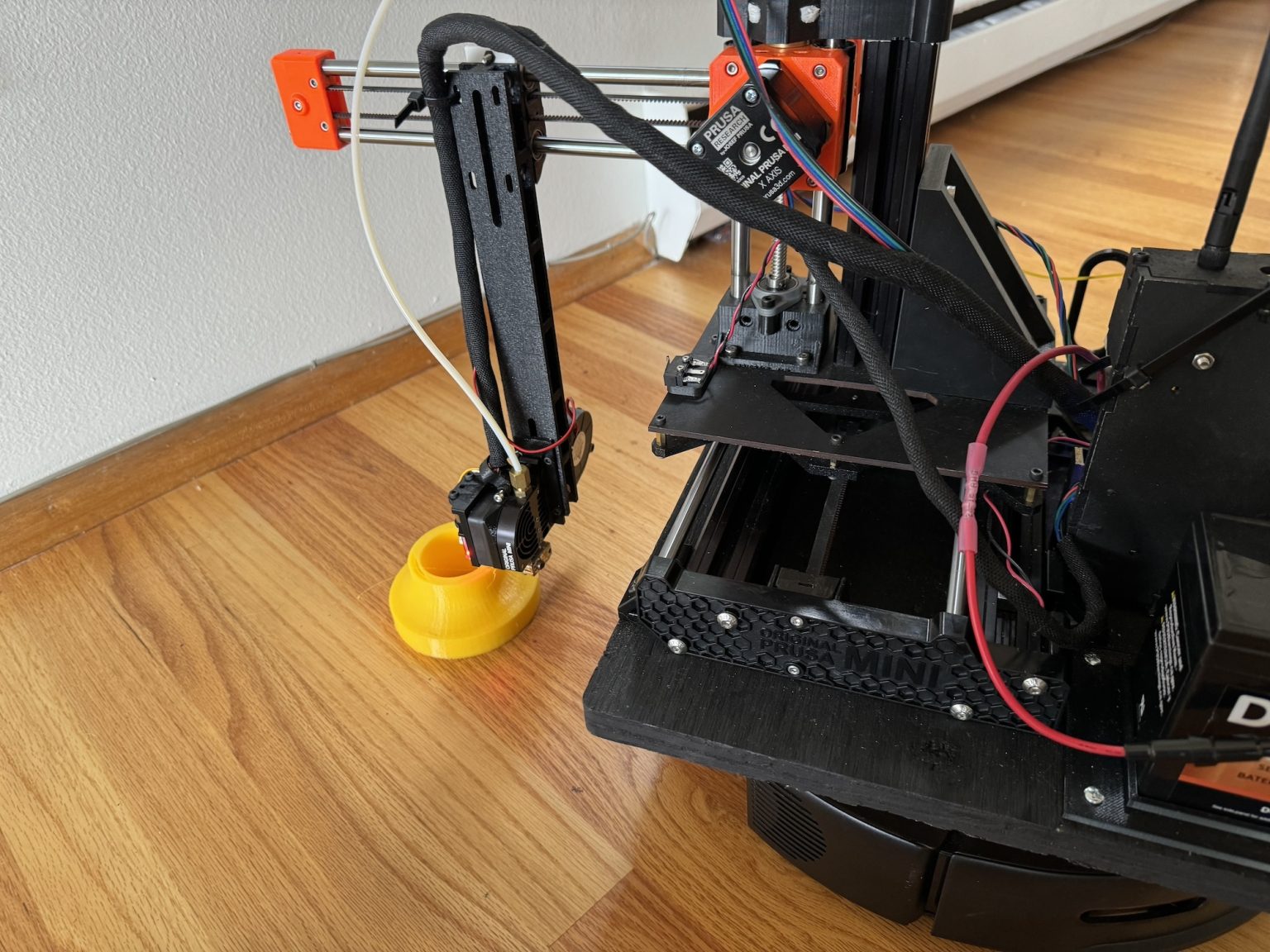

A new University of Washington project called MobiPrint is a mobile 3D printer that has the capability to automatically measure a room and then print objects onto the floor. This device, which is built onto a modified vacuum robot, offers a variety of possibilities when it comes to creating different objects, ranging from artistic pieces to accessibility features like tactile markers for blind individuals. Before printing begins, MobiPrint travels around an indoor space autonomously and uses LiDAR to map it. Users can then select a location on the map to print the object and work with a design interface to scale and position the job before the robot moves to the location and prints the object directly onto the floor using common 3D printing bioplastic.

The goal of MobiPrint is to expand the reach of 3D printing and make it easier for people to use. This includes changing the built environment and customizing spaces to fit specific needs, whether for accessibility or personal preference. Daniel Campos Zamora, a doctoral student at the Paul G. Allen School of Computer Science & Engineering, highlights the potential for 3D printing to impact the world in significant ways. The project was presented at the ACM Symposium on User Interface Software and Technology, and the research was funded by the National Science Foundation.

MobiPrint represents a significant advancement in the field of 3D printing by introducing mobility and automation into the process. By being able to move around a space, take measurements, and print objects directly onto the floor, this device opens up new possibilities for creating custom designs and accessibility features. The ability to autonomously map a room using LiDAR technology and then convert that map into an interactive canvas revolutionizes the way 3D printing can be integrated into everyday environments.

The prototype of MobiPrint is built onto a modified vacuum robot, showcasing the innovative approach taken by the University of Washington team. The project is a collaboration between researchers and designers to find new ways to utilize 3D printing technology for practical applications. By offering a design tool that allows users to upload designs or choose from a library of objects, MobiPrint makes the process of creating and printing objects more accessible and user-friendly. This project has the potential to have a significant impact on how spaces are customized and designed in the future.

The work on MobiPrint was presented at the ACM Symposium on User Interface Software and Technology, highlighting the interest and potential impact of this project in the field of technology and design. Liang He, an assistant professor at Purdue University and co-author on the paper, was instrumental in the development of this research. The project demonstrates the intersection of technology, design, and accessibility, showing how 3D printing can be used to create innovative solutions for a variety of needs. With funding from the National Science Foundation, the team was able to bring this project to life and show the possibilities of integrating 3D printing into everyday environments.

Overall, MobiPrint represents a significant step forward in the world of 3D printing, by introducing mobility and automation to the process. This innovative device has the potential to change how objects are created and customized in indoor spaces, offering new opportunities for artistic expression and accessibility features. By combining cutting-edge technology with user-friendly design tools, MobiPrint is paving the way for a more accessible and customizable future in the world of 3D printing.