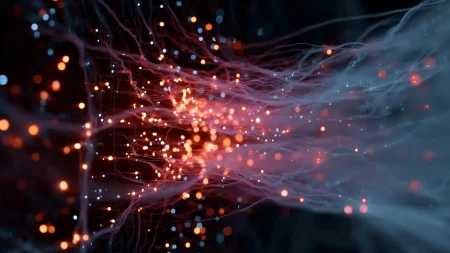

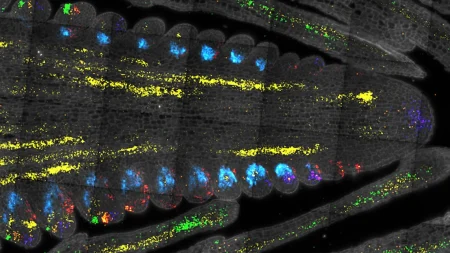

A new study has integrated machine learning, optimization, 3D printing, and stress experiments to gain insight into the intelligent approach to stress distribution in natural materials like bone, bird feathers, and wood. Engineers have developed a material that replicates the functionalities of human bone for orthopedic femur restoration, aiming to improve current methods of repairing fractured femurs that can cause complications like loosening, chronic pain, and further injury. Led by University of Illinois Urbana-Champaign professor Shelly Zhang, the study introduces a computational framework to produce a material that mimics bone and controls stress distribution through virtual growth simulation and machine learning algorithms.

Fractures of the femur, a common injury among elderly individuals, occur when stress concentrates at the crack tip, increasing the likelihood of fracture lengthening. Conventional surgical procedures involve attaching metal plates around the fracture with screws, but these methods can have drawbacks. The new approach to orthopedic repair developed in the study uses a fully controllable computational framework to produce a material that replicates the functionalities of human bone, optimizing stress distribution and architecture to provide support and protection to the fractured area.

The study findings, published in the journal Nature Communications, demonstrate how the team used a materials database, virtual growth stimulator, machine learning algorithms, and computational optimization to develop a bio-inspired material that mimics bone. By fabricating a full-scale resin prototype using 3D printing and attaching it to a synthetic model of a fractured human femur, the researchers were able to test its efficacy and confirm that it is possible to grow a synthetic material in a way similar to biological systems. This work has the potential to stimulate bone repair by offering optimized support and protection from external forces, showcasing the versatility and applicability of this technique in various biological implants.

The research was supported by the David C. Crawford Faculty Scholar Award from the University of Illinois Urbana-Champaign, highlighting the importance of this innovative approach to orthopedic repair. By focusing on the relationship between structure and physical properties in materials like bone, the study opens up possibilities for the application of this computational optimization algorithm to different types of materials, including metals, polymers, and more. With the emphasis on geometry, local architecture, and corresponding mechanical properties, the potential applications of this technique are vast and could revolutionize the way we approach stress manipulation and support in biological implants.