In a study conducted by scientists at Tokyo Tech, the encapsulation of copper nanoparticles within hydrophobic porous silicate crystals has been shown to significantly enhance the catalytic activity of copper-zinc oxide catalysts used in methanol synthesis via CO2 hydrogenation. This breakthrough innovation effectively inhibits the thermal aggregation of copper particles, leading to increased hydrogenation activity and enhanced methanol production. The findings of this study pave the way for more efficient methanol synthesis from CO2, which is crucial in the quest for emission reduction measures to combat global warming.

Carbon dioxide (CO2) emissions are a significant contributor to global warming, emphasizing the need for alternative fuels to reduce emissions from fossil fuels. Methanol has emerged as a versatile and cost-effective fuel, offering a promising alternative to conventional transportation fuels. To address the impact of CO2 emissions, there has been a focus on CO2 capture and utilization technologies, with methanol synthesis via CO2 hydrogenation emerging as a particularly promising approach. This method involves capturing CO2 from the atmosphere and converting it into valuable products like methanol, contributing to efforts to reduce greenhouse gas emissions.

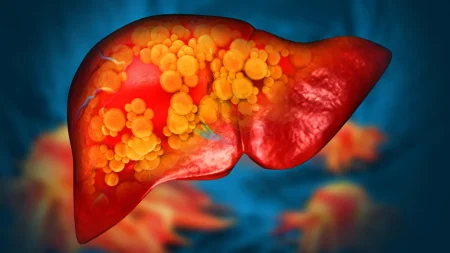

For methanol synthesis via CO2 hydrogenation, catalysts that exhibit high activity at lower temperatures are preferred due to the heat released during the reaction. Copper-zinc oxide (Cu-ZnO) based catalysts are favored for their ability to convert CO2 into formate intermediates that promote methanol production at the Cu-ZnO interface. To enhance production, increasing the surface area of this interface is crucial, which can be achieved by dispersing Cu nanoparticles. However, Cu nanoparticles are thermally unstable, aggregating during preparation and reaction, reducing the interface area and hindering methanol production. Additionally, water formation as a by-product accelerates Cu aggregation and inhibits formate formation.

The research team, led by Professor Teruoki Tago at Tokyo Tech, developed novel Silicalite-1 (S-1) encapsulated Cu-ZnO catalysts to address these challenges. By encapsulating Cu nanoparticles within porous materials like silica or zeolite, thermal aggregation of metals is mitigated, leading to enhanced catalytic activity. Their study, supported by the EU through Horizon2020 and the Japan Science and Technology Agency through SCICORP, demonstrated that the Cu@S-1 catalyst, in which Cu particles were encapsulated within S-1, showed higher hydrogenation activity and methanol production than traditional Cu/S-1 catalysts.

To further enhance methanol production, the researchers added ZnO to Cu@S-1, forming a ZnO/Cu@S-1 catalyst with fine Cu particles. This catalyst exhibited even higher activity, indicating the formation of the Cu-ZnO interface. The encapsulation structure with S-1 was found to suppress thermal aggregation of Cu particles while facilitating the rapid elimination of the water byproduct from the Cu-ZnO interface, enhancing methanol synthesis. Overall, the innovative encapsulation method demonstrated in this study offers a promising avenue for efficient methanol production from CO2, contributing to the development of sustainable fuel sources and emission reduction measures.