Entrepreneurship has become a common theme in the field of science, with engineers and scientists often leveraging their research to start new businesses. Bioproduction, which involves using living cells and organisms to manufacture products, is an area ripe for entrepreneurial opportunities. Biomaterials play a critical role in various industries, from pharmaceuticals and vaccines to packaging and textiles. Spider silk, known for its strength and elasticity, has garnered significant interest in biomanufacturing, with potential applications ranging from tactical gear to sutures and textiles.

A group of students from across the country, including Ghita Guessous from the University of California San Diego, conducted a comprehensive study on the challenges facing the spider silk industry. Despite never meeting in person, the team collaborated effectively, driven by their shared interest in researching innovation trends in biotechnology. The study, published in ACS Biomaterials and Engineering, drew on academic literature, market data, patents, and input from industry experts to provide an informed and data-driven perspective on spider silk production.

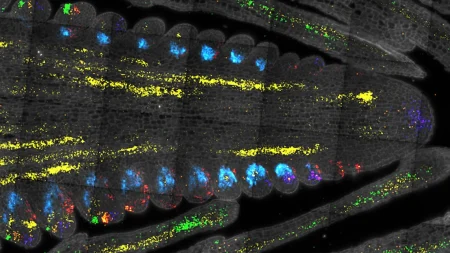

One of the main challenges in spider silk production is scaling up manufacturing, as spiders are territorial and cannibalistic, making large spider farms impractical. Scientists have explored genetically modifying other organisms to produce spider silk, such as goats, alfalfa, silkworms, yeast, and bacteria. Heterologous expression, or splicing spider-silk genes into other hosts, is a common approach, but addressing toxicity issues remains a key area of research. The team aimed to identify the most suitable host organisms by balancing quality and cost considerations.

The study highlighted the need for academic research to address the outstanding challenges in the spider silk industry. The team examined potential applications for spider silk, including fashion, high-performance materials, and personal care products. While fashion presents a lucrative market, breaking into an industry dominated by cheap synthetic materials like polyester can be challenging. High-performance applications, such as bulletproof vests and car panels, offer promising opportunities for spider silk. Despite the challenges identified, the team remains cautiously optimistic about the future of biomanufacturing.

The findings from the study underscore the importance of considering scalability before launching new ventures in biotechnology. By providing insights into the challenges and opportunities in spider silk production, the study serves as a valuable resource for academic research programs and entrepreneurial decisions. While the team may approach future ventures more cautiously, they remain hopeful that their study will inspire the next generation of revolutionary startups in the biomanufacturing space. Collaborating with students from various universities, the team leveraged their diverse skills and expertise to conduct a thorough analysis of the spider silk industry.