Summarize this content to 2000 words in 6 paragraphs Dartmouth and Southern Methodist University researchers invented a technique that uses a specialized light projector and a photosensitive chemical additive to imprint two- and three-dimensional images inside any polymer. The light-based engraving remains in the polymer until heat or light are applied, which erases the image and makes it ready to use again. The technology is intended for any situation where having detailed, precise visual data in a compact and easily customizable format could be critical, such as planning surgeries and developing architectural designs.

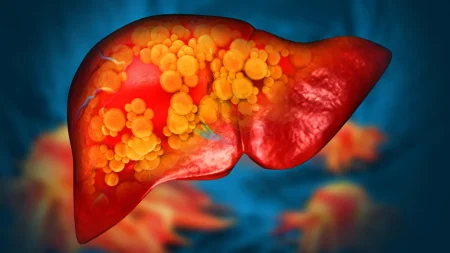

Imagine if physicians could capture three-dimensional projections of medical scans, suspending them inside an acrylic cube to create a hand-held reproduction of a patient’s heart, brain, kidneys, or other organs. Then, when the visit is done, a quick blast of heat erases the projection and the cube is ready for the next scan.

A new report in the journal Chem by researchers at Dartmouth and Southern Methodist University (SMU) outlines a technical breakthrough that could enable such scenarios, and others with widespread utility.

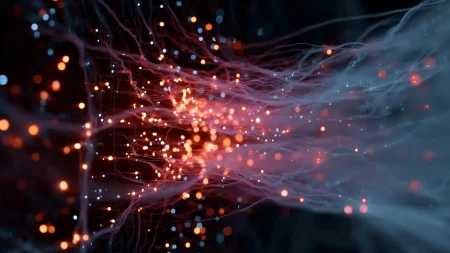

The study introduces a technique that uses a specialized light projector to imprint two-dimensional and 3D images inside any polymer that contains a photosensitive chemical additive the team developed. The light-based engraving remains in the polymer until heat is applied, which erases the image and makes it ready to use again.

In short, the researchers write with light and erase with heat or light, says Ivan Aprahamian, professor and chair of chemistry at Dartmouth and co-corresponding author on the paper. In test trials, the researchers produced high-resolution images in polymers ranging from thin films to six inches thick.

The technology is intended for any situation where having detailed, precise visual data in a compact and easily customizable format could be critical, Aprahamian says, such as planning surgeries and developing architectural designs. The device also could be used for generating 3D images for education and even creating art, he says.

“This is like 3D printing that is reversible,” Aprahamian says. “You can take any polymer that has the optimal optic properties — that is, it’s translucent — and enhance it with our chemical switch. Now that polymer is a 3D display. You do not need virtual reality headsets or complicated instrumentation. All you need is the right piece of plastic and our technology.”

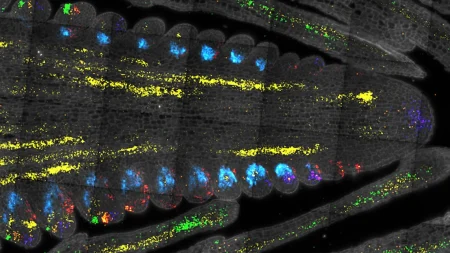

Readily available polymers — such as an acrylic cube — could be transformed into a display with the addition of the light-sensitive chemical “switch” formulated by Aprahamian and Qingkai Qi, a postdoctoral researcher at Dartmouth and the study’s first author. The switch consists of a compound called azobenzene that reacts to light paired with boron difluoride, which enhances the switch’s optical properties.

Once integrated with a polymer, the switch reacts to wavelengths of red and blue light beamed from a projector developed in the lab of Alex Lippert, professor of chemistry at SMU and co-corresponding author of the study. Study co-author Joshua Plank is a PhD candidate in Lippert’s lab. The red light acts like ink by activating the chemical additive to create the image, Aprahamian says. Blue light can then be used to erase it.

The projector illuminates the treated polymer from different angles with various patterns of light, Lippert explains. The photosensitive chemical developed in Aprahamian’s lab at Dartmouth is activated where these patterns intersect to produce 3D patterns. Creating 3D projections from 2D images such as a chest X-ray would mean projecting slices of the original image into a polymer cube or other shape until the slices combine to form the full 3D image, Lippert says.

The researchers have been able to produce animated images in polymers and future work revolves around improving that process. In the meantime, the technology reported in Chem could be developed for practical use in its current form, such as for industry or health care.

“Scaling up requires tuning the chemical switch properties to improve resolution, contrast, and refresh rate,” Lippert says. “The projector system can in principle be scaled up and developed into a turnkey system with automated hardware and associated software for easy use.”