The research team at the University of Virginia School of Engineering and Applied Science led by Professor Osman E. Ozbulut has focused on exploring the potential benefits of incorporating cellulose nanofibrils in 3D-printed concrete. This innovative plant-based material has the potential to enhance the sustainability and durability of structures built using 3D printing technology. The team’s findings, set to be published in the September 2024 issue of Cement and Concrete Composites, suggest that the inclusion of cellulose nanofibrils could lead to more resilient and eco-friendly construction practices in the near future.

3D-printed concrete buildings are a growing trend in the construction industry due to their quick, precise construction, reduced labor costs, and potential for intricate designs. However, current printable materials are limited, and concerns regarding their sustainability and durability persist. Professor Ozbulut highlights the challenge of balancing flow properties for easy fabrication with the need for critical properties like mechanical strength, interlayer bonding, and low thermal conductivity. Cellulose nanofibrils, derived from wood pulp, show promise as an additive to improve the rheology and mechanical strength of these composites.

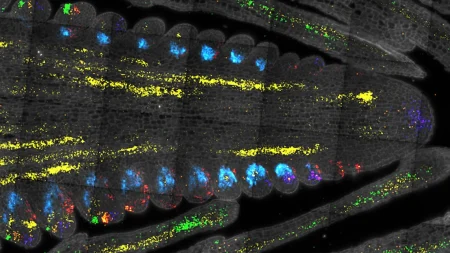

Despite the potential benefits of cellulose nanofibrils as an additive in 3D-printed concrete, the influence of CNF on conventional composites had not been thoroughly explored before the UVA-led team’s study. Addressing the need for more scientific understanding of additive effects on 3D-printed structures, the team conducted experiments with varying amounts of CNF additive and found that a minimum of 0.3% CNF significantly improved flow performance. Microscopic analysis of hardened samples revealed enhanced material bonding and structural integrity. Furthermore, CNF-enhanced 3D-printed components demonstrated resistance to pulling, bending, and compression in lab testing.

The research conducted by Professor Ozbulut’s team at UVA sheds light on the potential of cellulose nanofibrils to enhance the performance of 3D-printed concrete structures. By carefully studying the effects of CNF additives on material properties, the team has identified opportunities to improve the flow and mechanical strength of 3D-printed composites. These findings pave the way for incorporating renewable and low-impact materials like CNF into commercial printable materials, creating more resilient and eco-friendly construction practices.

The incorporation of cellulose nanofibrils in 3D-printed concrete could lead to more sustainable and durable construction practices in the future. By enhancing the flow properties and mechanical strength of 3D-printed composites, CNF additives offer a promising solution to the challenges facing the construction industry. The UVA-led research team’s meticulous study has provided valuable insights into the benefits of using CNF in 3D printing technology, highlighting the potential for more resilient and eco-friendly structures in the years to come.